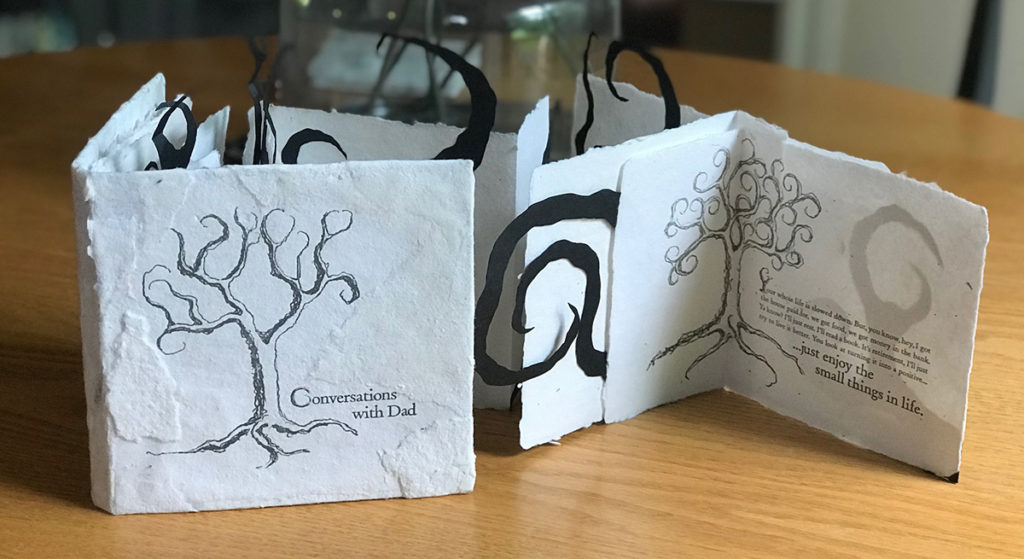

I first made paper when I was going to grad school at uw-madison. I was working on my masters in graphic design and I wanted to have some fun, so I took book making. It was fun! I won’t kid you, being an art major is too good to be true and so is being a graphic designer. I have absolutely loved my career. Back to paper making.

Part of the bookmaking class was actually making the paper for the books. We learned about different binding methods, printing, etc. The classroom for paper making was amazing. It had two pulping machines–large containers with sort of a lazy river and grinding system. We brought in used fabric made of 100% cotton and cut them into 2″ scraps. I went to the local resale shop and picked up some sheets, t-shirts and tablecloths. The scraps of fabric flowed around the lazy river, and at one point, funneled through grinders. Over the course of a few hours, the fabric turned into pulp–a mush of cotton.

The classroom also had large sinks, drains in the floor, huge buckets, screens large and small, drying racks and a hydraulic press to squeeze water out of the paper. I don’t have any of that at home, but paper making is still fun.

You’ll need a few things. The screen is essential. A bin can be used to screen the pages. If you buy a kit, it may come with a sheet of felt-like material. That’s fine, but I recommend finding an old wool blanket and cutting it into squares slightly larger than your screen. I found my old army blanket at the local resale shop. Wool is key. When you peel off the screen, you want the pulp to stick to the wool.

Basically, as the video shows, have a bucket of pulp and another container to screen the pulp. If you are looking for consistency, start with enough pulp to create the desired thickness and then add consistent amounts back in after making each sheet to maintain that thickness.

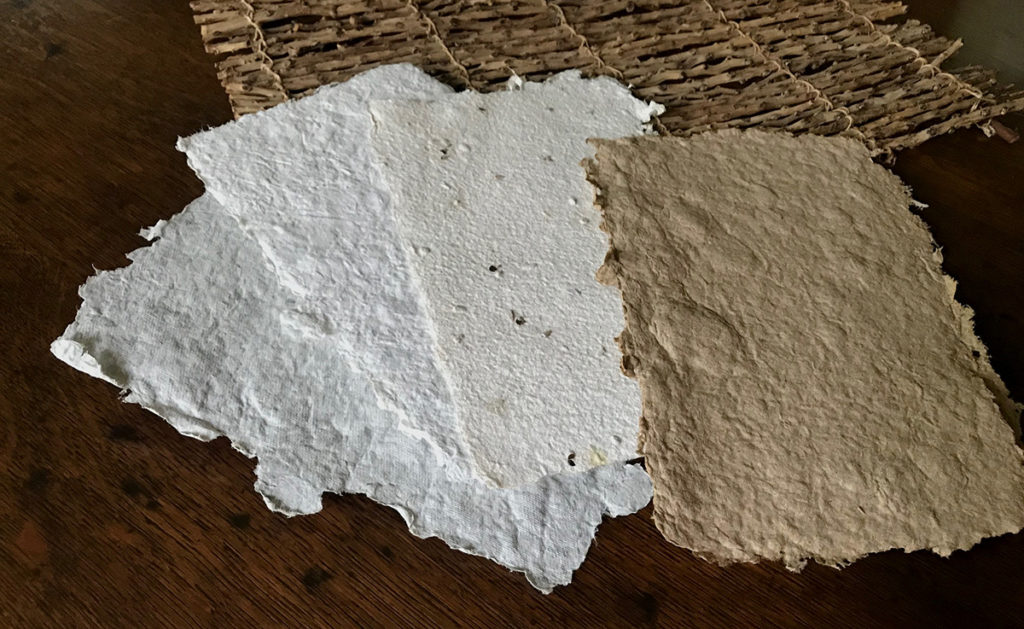

The pulp can be bought ready to go. Just ad water and depending on the quality, you probably want to soak in water overnight to make sure it’s loose. For the brown pulp, I used some packaging. It looked similar to egg carton material. I tore it into 2 inch squares and soaked it overnight. By the next morning it was broken down into mush. I ran my mixer through it to break up any chunks.

Leave the sheets of paper on the wool until completely dry. They may curl up if you them off early. The lawn chairs and table provided a great place to work. The screen on the table allowed the water to drip down and screen on the chairs made for fast drying.